Cured-In-Place Pipelining (CIPP) Options:

Steam Cured CIPP offers a proven trenchless repair of aging laterals with a minimum

50-year lifespan at a fraction of the cost of dig and replace. A resin impregnated

flexible tube is inverted, inflated, and then cured in place using heat. The CIPP liner

conforms to the walls of the host pipe resulting in a smooth, seamless new pipe for

lengths up to 120’ from the mainline and 360-degrees of the mainline.

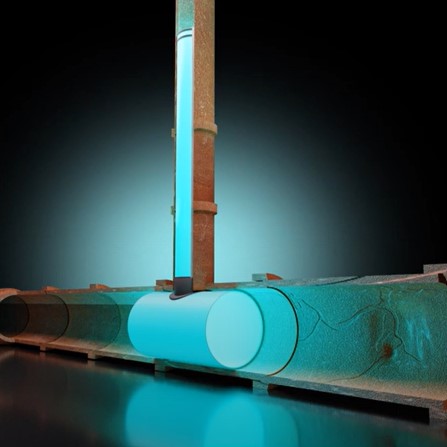

UV-Cured CIPP provides the same 360-degree and lateral benefits as steam cured

with a quicker return to service. For systems that only require lining up to 10 feet

from the mainline or budget conscious installations, this new installation method is a

perfect fit

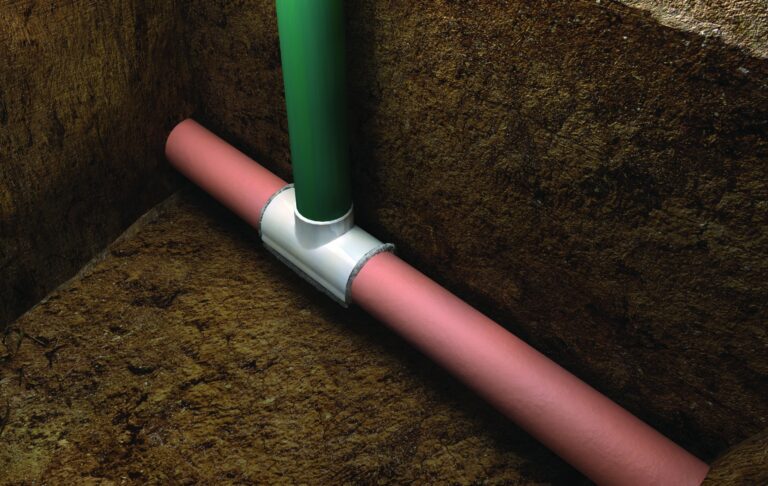

Vac-A-Tee Installation:

A trenchless outside cleanout system that allows access to the lateral pipe for

cleaning, inspecting, and lateral lining. ASTM F2097 compliant, it can be installed on pipe diameters of 6” or less at depths up to 15 feet.

Lateral Grouting:

the exterior of the structure. This trenchless application can be applied to both the

mainline intersection as well as the lateral pipe from the mainline up to 30 feet or for

the full length of the lateral through a clean out.

The Benefits of Lateral Rehabilitation:

• Quick return to service.

• Environmentally friendly.

• No need to enter residences.

• Cost Effective.

Related Services provided by Hoerr Construction:

• CCTV

• Lateral Locating

• Lateral Inspection

• Mainline CIPP

• Joint Sealing

• Manhole Rehabilitation.