What Is a Geopolymer?

Geopolymers are amorphous three-dimensional alumina-silicate binder materials. In

the 1970s, Joseph Davidovits discovered that under the right set of conditions these

components could fully react with one another to form an extended polymeric

network. Geopolymer mortar has a chemical structure like a natural stone – similar to

zeolites or quartz.

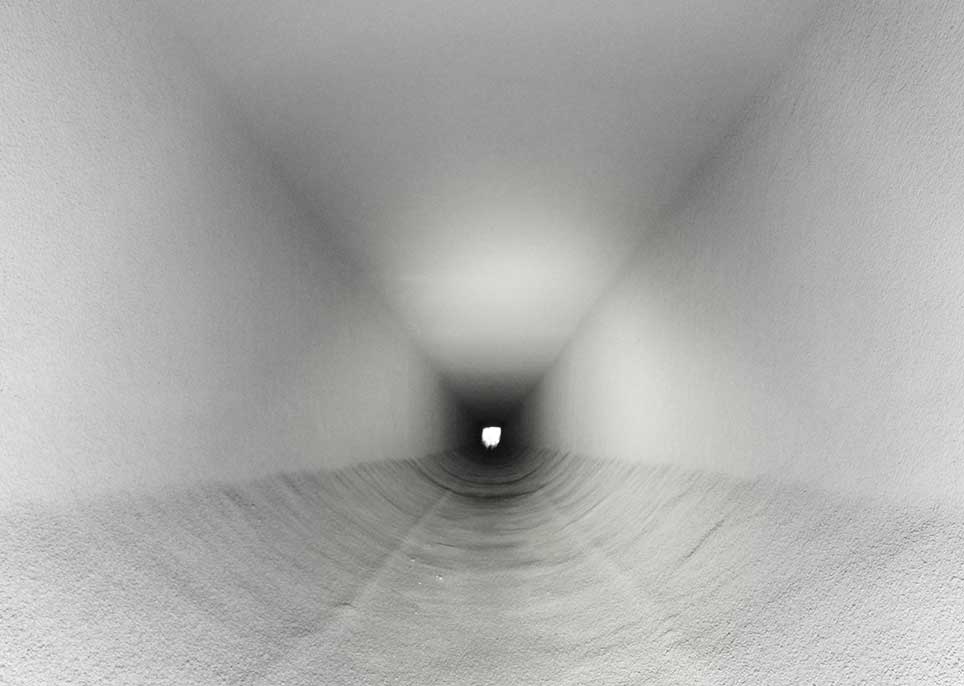

Geopolymer As a Lining Material

Geopolymer mortar has the look and feel of most standard cements. The

geopolymer powder containing pozzolans is mixed directly with water that results in

a fiber reinforced. Compressive, tensile, and flexural properties of geopolymer

mortar have been engineered to exceed those of a standard cement while

maintaining an ultra-low porosity and high self-bonding that eliminates cold joints. It

continues to react with itself for decades, building additional strength and enhancing its service life expectancy.

Engineered and Accepted

With a high flexural strength designed to reach 1500 psi at 28 days (ASTM C78), and

NSF 61 and WRAS certifications, geopolymer mortar has been recognized and accepted as a fully structural pipe rehabilitation solution for many municipalities,

Counties, and State Departments of Transportation.

The Solution is Hoerr.

Our holistic approach to sewer rehabilitation includes Geopolymer applications for

large diameter culverts and sewer pipes. It is effective on various pipe materials:

corrugated metal, concrete, and bricks/blocks. Geopolymer mortar can be applied

with precision to odd shapes and sizes as Hoerr’s experienced applicators employ

multiple techniques including pouring, troweling, spraying, and centrifugal/spin

casting while maintaining a minimal installation footprint.

Benefits of Using

Geopolymer for Rehab:

• Fully Structural Solution

• Trenchless Technology

• Quality Controlled Application Process

• Minimal Installation Footprint

Related Services provided by Hoerr Construction:

• Clean / CCTV Inspections

• I & I Control

• Storm Culverts

• CIPP